SLA or Stereo Lithography Appearance, is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to the surface of the photopolymer vat. And the resin is solidified and forms form dots to lines and then to a single layer of the desired 3D object. Then, the build platform lowers one layer and a blade recoats the top of the tank with resin repeatedly until the 3D object is complete.

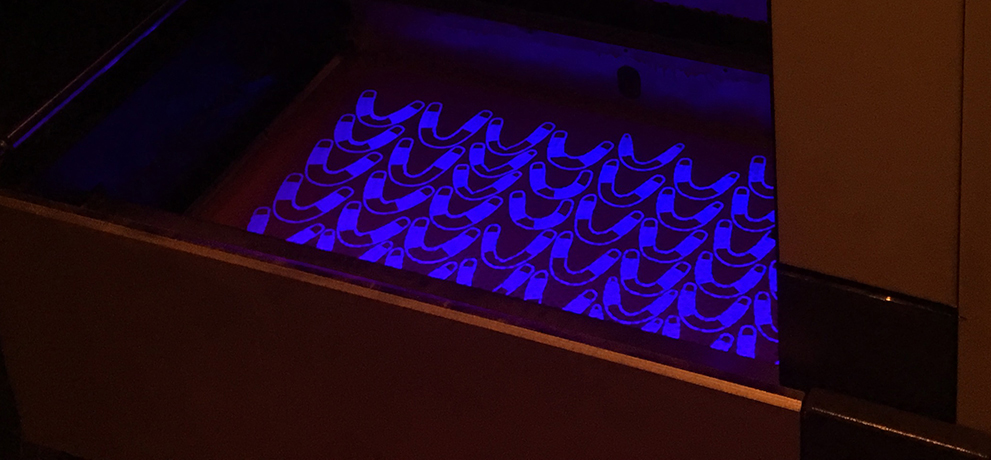

SLA is an early and widely applied rapid prototyping technology using liquid photosensitive resin. First, the 3D solid model is depicted by CAD, and the discrete program is used to slice the model and draw the scanning path. The data generated will accurately control the movement of LCD or laser scanner and lifting platform. The LCD or the laser beam is irradiated onto the surface of the liquid photosensitive resin by the scanning path controlled by the numerical control device, so that a layer of resin in a specific area of the surface is solidified, and a section of the part is generated; Then, the lifting platform is lowered by a certain interval, another layer of liquid resin is masked on the solidified layer, and afterwards the second layer is scanned to firmly bonded to the previous layer, so the layers are superposed to form a 3D workpiece prototype. After the prototype being taken out of resin and the post-curing, and the desired product is obtained by polishing, plating, painting or coloring.

Excellent stability, full automation through whole procedure High precision in large format

The accuracy of prototypes could reach ±0.1mm(<100mm);±0.1%(>100mm)

Except laminated striations on the side and bending surface, a glassy effect can still be obtained on the upper surface

Be capable of printing delicate and complex objects

The vacuum disposable model can be made directly for precision casting

Prototypes could replace the plastic molds to some extent

Excellent stability, full automation through whole procedure High precision in large format

The accuracy of prototypes could reach ±0.1mm(<100mm);±0.1%(>100mm)

Except laminated striations on the side and bending surface, a glassy effect can still be obtained on the upper surface

Be capable of printing delicate and complex objects

The vacuum disposable model can be made directly for precision casting

Prototypes could replace the plastic molds to some extent